In Pakistan, most plant managers and utilities engineers know the feeling when gas pressure suddenly drops. Steam demand is high, safety margins are low, and the boiler is right in the middle. Trips, alarms, operator stress, and phone calls from production all come together at once.

Over the last 20+ years, working with industries across Pakistan, we have seen that fuel is no longer just a line item in procurement. It is directly linked to business continuity. That is why dual-fuel Weishaupt burners on Bosch steam boilers have become such an important part of our conversations with clients. They are not just ‘another option’, they are a strategy to move from fuel crisis to fuel flexibility.

The Real Gas Situation in Pakistani Plants

On paper, many plants are designed as gas-fired installations. In reality, gas pressure is inconsistent, curtailments are frequent, and forecasts are uncertain. This is not an abstract macroeconomic issue. It shows up in your boiler house.

Low gas pressure leads to unstable combustion. Burners struggle to stay in range. Operators are forced to intervene manually. Trips become more frequent. In some cases, lines are stopped simply because steam cannot be guaranteed at the required pressure and flow.

We often hear similar stories during site visits: backup boilers that are outdated, fuel tanks that are there but not integrated into a proper dual-fuel strategy, and production plans that are always ‘at the mercy of gas.’ In this environment, depending on a single fuel is a technical risk and a strategic risk.

What a Dual-Fuel Bosch & Weishaupt System Actually Does

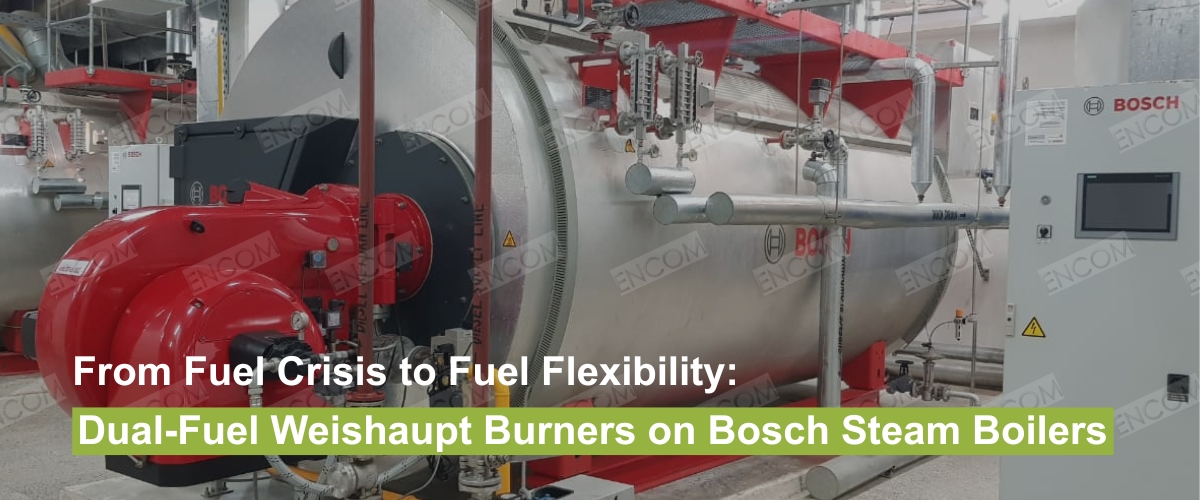

A dual-fuel Weishaupt burner is designed to operate on gas and oil on the same boiler, with proper combustion control for each fuel. When we combine this with a Bosch industrial steam boiler, the result is a matched system rather than a collection of parts.

The boiler heat transfer surfaces, firing chamber, and controls are engineered together with the burner. The dual-fuel burner is sized for your required steam output and your local fuel specifications. The control system is configured so that switching between gas and oil is safe, repeatable, and manageable for your operators.

In normal conditions, you can operate primarily on gas for convenience and cost. When gas pressure falls outside the safe operating range, the burner can change over to oil. The boiler remains online. Steam supply continues without needing a second, separate boiler to take over.

Business Continuity When Fuel is Uncertain

From an operational point of view, this is not just about having two fuels in theory. It is about staying in control when the external situation changes.

With a dual-fuel Bosch & Weishaupt setup, you can keep critical loads supplied even if gas is curtailed suddenly. You reduce the risk of full plant shutdowns caused by gas-only dependency. You gain time to respond, communicate, and plan, instead of reacting in crisis mode each time supply is disrupted.

For plants with continuous or export-focused production, the cost of one major shutdown can easily justify the investment in dual-fuel capability. Avoiding lost batches, missed shipments, or damaged equipment is often worth more than the fuel bill itself. Resilience becomes a measurable outcome, not only a nice idea.

Fuel Flexibility, ROI, and Long-Term Strategy

Fuel flexibility is not limited to emergencies. It can also be used to optimize your long-term cost and compliance strategy.

Many of our clients choose to run on gas when prices and availability are favorable and shift more operating hours to oil when gas becomes constrained or commercially less attractive. Because they are not locked into a single fuel type, they have more bargaining power with suppliers and more options when planning annual budgets.

Over the life of a Bosch steam boiler, this flexibility has a real impact on total cost of ownership. At the same time, modern Bosch–Weishaupt systems support efficient combustion, good heat transfer, and proper emissions control when combined with regular tuning and flue gas analysis. That helps with both operating cost and regulatory compliance.

How Encom Pakistan Fits into the Picture

Technology alone is not enough. Dual-fuel systems only deliver their full value when design, integration, and service are handled correctly.

At Encom Pakistan, we represent Bosch industrial steam boilers and Weishaupt burners as their partners in Pakistan. Our role is to look at your plant as a whole. We start with your steam demand profile, your current and expected fuel situation, and your process criticality. From there, we help define whether a dual-fuel solution is justified and what configuration makes sense.

We then handle system design, supply, installation, and commissioning with OEM-certified engineers. Our team is trained at Bosch and Weishaupt facilities, so we understand both the combustion side and the boiler side in detail. After commissioning, we stay involved through routine maintenance, burner tuning, troubleshooting, and 24/7 support with original spare parts.

If your plant is still dependent on a single fuel, or you are planning a new boiler project, this is the right time to think in terms of fuel flexibility instead of just fuel availability. We are always ready to sit down with your team, review your current setup, and explore how a Bosch steam boiler with a dual-fuel Weishaupt burner could help you move from crisis management to a more stable and strategic way of running your boiler house in Pakistan.